Espey WKA3

April 13, 2019

DMG1

April 19, 2019Espey WDB200

Features

- Torque transmission depending on application with set screw or as shrink fit

- Metallic coating (FMP 84) basically for applications without high oxidation

- Ceramic coating (EMP 98) basically for applications with high oxidation

- Design one- or two-piece

Advantages

- Easy installation by split design (2-piece version)

- High reliability

- Long-term operation time

- Maintainability

Operating range

FMP 84 (metallic coating)

General description: chromium carbide

Coating process: flame spray technique (no influence on material structure)

Shrink acceptability: very good

Shaft diameter: d = 45 … 340 mm (1.77″ … 13.39“)

Operating temperature: t = max. 1,000 °C (1,832 °F)

Peripheral velocity: vu = max. 240 m/s (787 ft/s)

Hardness: >65 HRC

EMP 98 (ceramic coating)

General description: chromium oxide (ceramic)

Coating process: flame spray technique (no influence on material structure)

Shrink acceptability: with restrictions

Shaft diameter:

d = 45 … 340 mm (1.77″ … 13.39“)

Operating temperature:

t = max. 600 °C (1,112 °F)

Peripheral velocity:

vu = max. 150 m/s (492 ft/s)

Hardness: >58 HRC

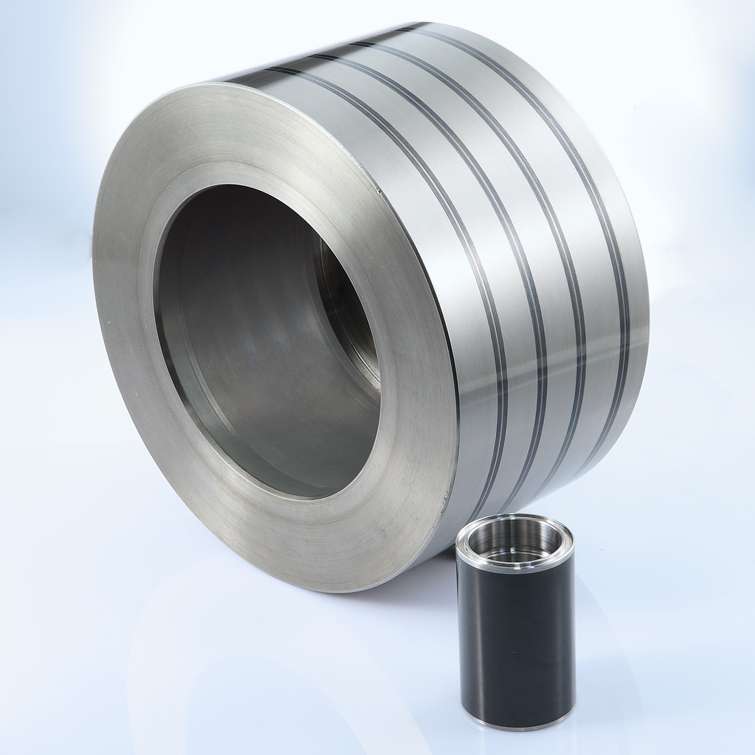

Materials

1.4021-FMP, 1.4086, 1.4462-FMP, 1.4571-FMP, others

Standards and approvals

- DIN 42955

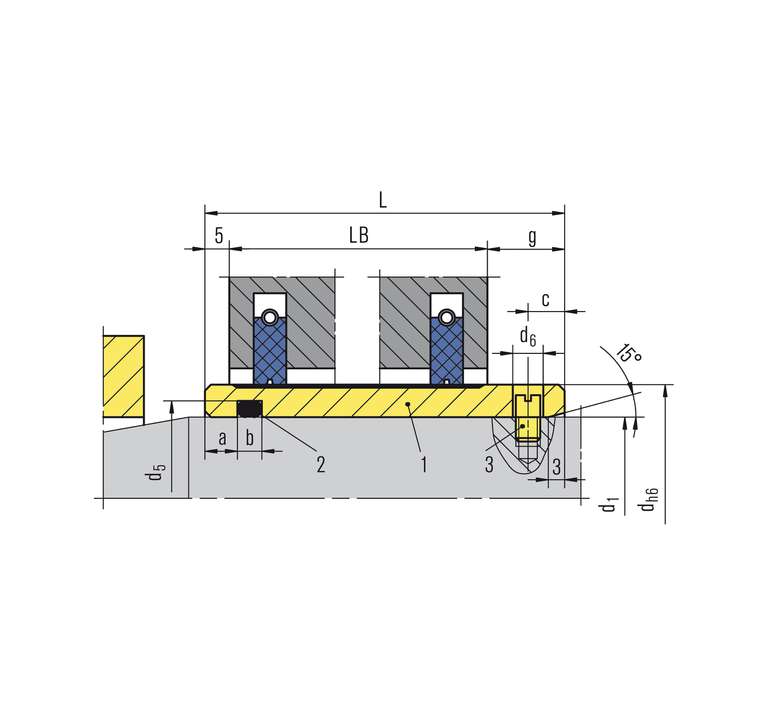

| Item | Description |

| 1 | Shaft sleeve |

| 2 | O-Ring |

| 3 | Set screw |